Data logger test for transport monitoring

In cooperation with the German Insurance Association (GDV e.V.), MONILOG® RISK LOGGER were sent on a journey - by rail and by ship - to answer the question of what stresses affect goods in transit.

For some years now, there has been an alternative for transport between Asia and Europe: the railway. On the "new" or "iron silk road", it brings goods to their destination in half the time of a container ship and costs significantly less than transport by air. The share of this transport route is still small, but the numbers are rising steadily. In 2021, around 30 trains already travelled the more than 11,000 km long overland route every day. On the two-week journey, the trains not only pass several national and customs borders, but also deserts. Temperatures vary greatly here: it can be very hot during the day and bitterly cold at night. Skill is also required: Because the track widths are not uniform, the wagons have to be rerouted.

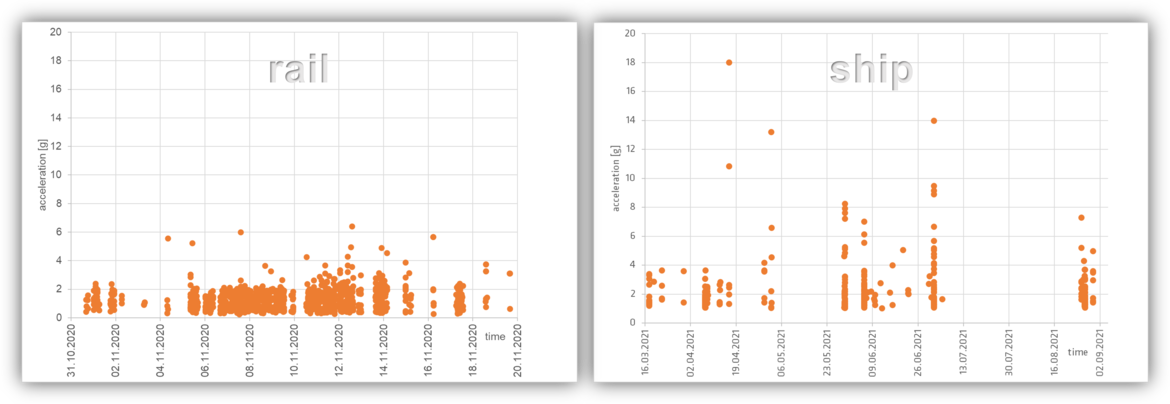

It is important to find out which goods can be transported by rail and how they are to be packed in the process. Even when shunting, the individual wagons travel on top of each other at just under 10 km/h and almost without damping. Deutsche Bahn, for example, specifies accelerations of 4 g as the maximum limit value for this. The so-called rail impacts represent an additional load. The rails are not seamlessly welded, as they are in our latitudes. Due to the temperature differences, the rails must be able to expand and therefore have small gaps. For the cargo, this means additional stress, because it is exposed to continuous vibrations. In the worst case, sensitive electronics will become inoperable, or the goods will suffer a total loss.

Therefore, it is important to obtain valid data on the different modes of transport and to find out which route is safest for the goods. For this reason, the MONILOG® RISK LOGGER was sent on its journey - by rail and by ship - in cooperation with the loss adjusters of the German Insurance Association (GDV e.V.).

Travel dates and trial description

GDV's partner DB Schenker carried out a total of four test rail journeys with accompanying measurements. The transports always took place from Europe to Asia. The four measurement periods were spread out over the year, so that the influences of the climate zones passed through were recorded as well as those of the seasons.

In contrast to the rail transport, the measurements of the sea transport were carried out in both directions, starting in Bremerhaven to Busan in South Korea and back again. The journey took place from 17 March to 30 August 2020 and lasted a total of 24 weeks or 167 days. The test sheets as transported goods were packed in different materials. The packaging materials used were aluminium compound foil, VCI foil (Volatile Corrosion Inhibitor) and polyethylene foil (PE). In addition, desiccant bentonite (according to DIN 55473(A)) with 32 desiccant units (TME) each was used for the aluminium composite and PE packaging. A measuring device was mounted in each of the three "packages". In total, SMT ELEKTRONIK GmbH mounted eight MONILOG® RISK LOGGER in the container.

With the help of humidity and temperature sensors, the data loggers continuously recorded the measured values at fixed time intervals from 5 to 120 min. In contrast, the shocks were recorded event-driven by acceleration sensors, namely when the predefined limit value of 0.3 g was exceeded.

Summary of the measurement results

The expectations that rail transport is robust compared to sea transport are basically confirmed. I.e., the stresses on the transported goods in terms of shocks and vibrations are higher. However, the differences in height are not so decisive. It is much more the case that the goods transported by rail are permanently subjected to shocks and vibrations over long periods of time. Put simply, in rail transport the shocks occur during the journey. In contrast, no mechanical stresses are measurable during sea transport as long as there are no waves. Here, the shocks occur mainly during reloading in the ports. The impact sensors of the data loggers measured the same high accelerations as for rail transportation. With both transport methods, the packaging must be adapted to the mechanical loads. The customer has to know his goods or product regarding the limit values of accelerations. In case of doubt, the transport should be monitored with a MONILOG® RISK LOGGER.

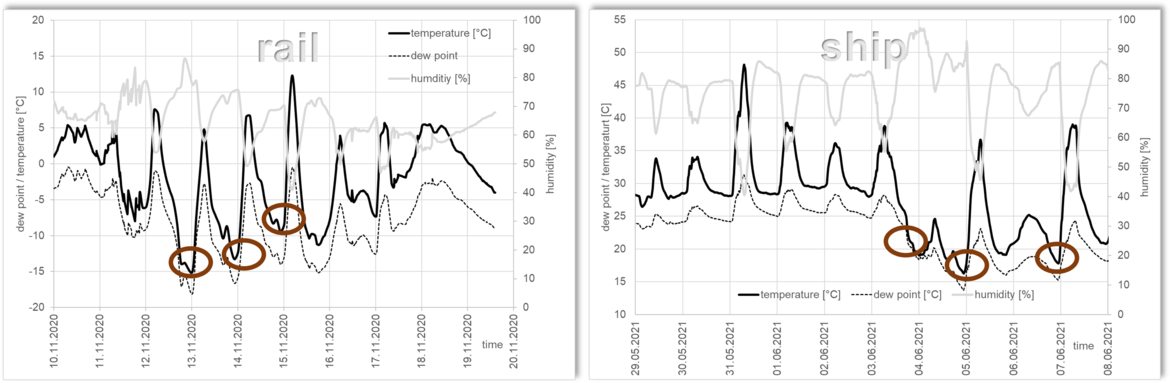

Fluctuating temperatures are significant in three respects during rail transport and must therefore be considered when choosing the means of transport. Large differences in temperatures occur between day and night, but also due to different climate zones passed through during a journey. Likewise, large differences in temperature must be considered, which occur during repeated journeys due to the seasons. Deep sub-zero temperatures are possible from spring to autumn. The strongly fluctuating temperatures between day and night in combination with humid air can lead to condensation. During transport by ocean-going vessel, this phenomenon of high temperature differences of up to 40 K between day and night has also been demonstrated. Here, too, high humidity of over 70 % then leads to water deposits.

This shows that temperature monitoring during transport is highly relevant. Measuring the humidity and temperature of the transported goods provides certainty about the condition of the surrounding climate. The use of desiccants in combination with tight plastic foils is highly recommended.

Great climate? - Unfortunately, water deposits formed and damaged the products

Due to unguarded stops in railway stations, on open tracks or even at national borders, unauthorized access to goods during rail transport is possible and has been proven. The risk of theft is very high compared to sea transport. However, the total loss of an entire container is much rarer in rail transport than in sea transport, where containers sometimes go overboard due to heavy seas, for example.

To be honest, we were very surprised at how often the containers were opened without permission during rail transport.

For all types of transport, it is advantageous to know what influences can affect the goods being transported or have affected them during transport. This is the only way to prevent damage or to react immediately in the event of damage. In transport monitoring, MONILOG® RISK LOGGER provide precise data on the condition of your product.

Fitting products

MicroShockDetectorplus

Small lightweight shock data logger with communication via USB and NFC. Also approved for air freight. Status report can be read out with smartphone and free app.

EnDaLsmart

Compact logger, especially suitable for monitoring large transports. With an integrated GPS receiver and inclination sensor. Also approved for air freight.